Kumatech is the first to receive the RWAAS solution from Valk Welding

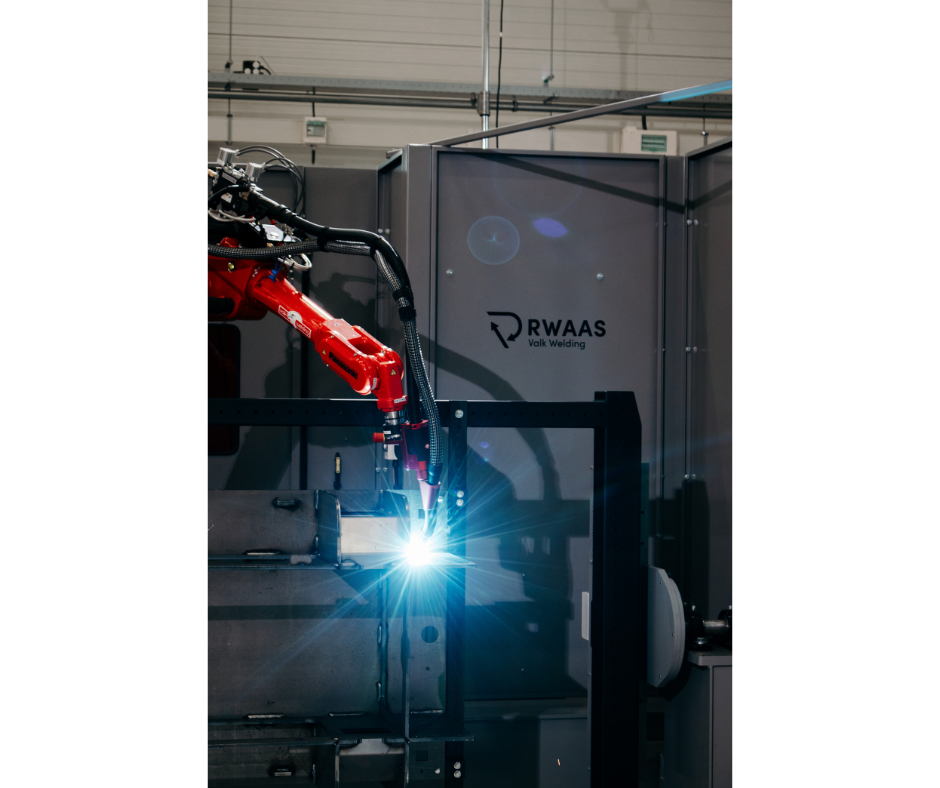

Kumatech, a fast-growing scale-up focusing on ‘best buy AGVs and total solutions for internal logistics’, is the first to receive Valk Welding’s RWAAS solution. RWAAS stands for Robot Welding As A Service and offers a unique all-in service package from Valk Welding. For a predictable monthly fee, you can have a welding robot system in production, without any investment or intensive, lengthy process. All wear parts and even unlimited welding wire for the RWAAS robot system are included. The RWAAS robot system was delivered to Kumatech in the morning and was already in production by the afternoon.

Why did Kumatech choose RWAAS?

Kumatech chose RWAAS instead of investing in the purchase of a welding robot. The choice for RWAAS was made due to the rapid growth of the company and because it allows for optimal use of financial resources. The RWAAS solution was operational within one day, allowing the company to continue its production and growth.

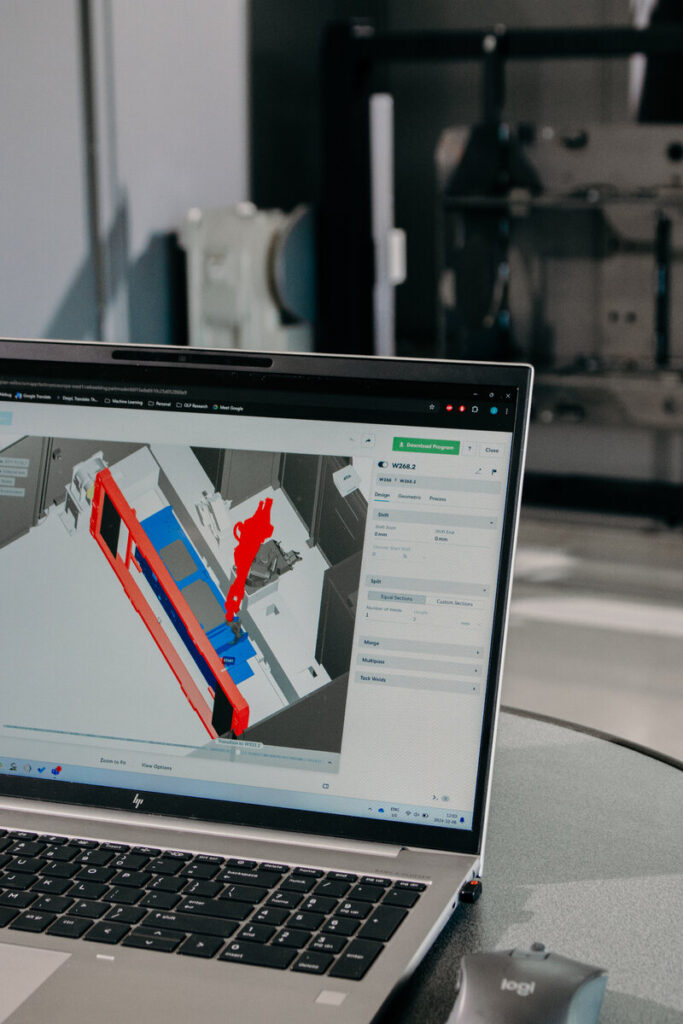

When signing up for RWAAS, Kumatech also gained access to the ARP powered by ArcNc software, which can be used to automatically program a robot. Thanks to the ARP powered by ArcNC software, programming a welding robot has been reduced from several hours to just 15 minutes. This is a huge difference in time compared to traditional programming. This concept also offers a perfect trial period for later investment in the purchase of its own welding robot, with the aim of growing with the same team and investing in smart automation.

Advantages of the robot

The welding robot does not replace people, but enables Kumatech to focus on more challenging work. Two employees, Joep and Teun, have completed operator and ArcNC training and can now fully programme and operate the robot. By investing in RWAAS, Kumatech can respond quickly to market demands and is not dependent on suppliers or finding manual welders.

Vision for the future

Kumatech strives for the ‘best buy’ AGVs and is very cost-conscious when it comes to production resources. In the long term, they want to integrate more intelligence into the welding robot to guarantee the quality and performance of the company. Machine learning and artificial intelligence are no longer fashion trends, but essential parts of their strategy. ARP powered by ArcNC is an important key to this.

Kumatech is looking forward to the next step of ARP powered by ArcNC, in which small design changes and different product variants will be automatically recognised, analysed and programmed without human interaction. They are pleased that Valk Welding is the first to market this total concept, which will help many companies take an important step forward.