Automatic Robot Programming with QPC

Automatic Robot Programming (ARP) often seems a long way off for companies with a wide variety of products within the same product families. It is often thought that a separate welding programme must be programmed for each variant of the product.

The Quick Program Configurator (QPC) software developed by Valk Welding changes this. QPC applies automatic robot programming precisely in situations where there is a wide variety of products within the same product families.

Automatic Robot Programming (ARP) often seems a long way off for companies with a wide variety of products within the same product families. It is often thought that a separate welding programme must be programmed for each variant of the product.

The Quick Program Configurator (QPC) software developed by Valk Welding changes this. QPC applies automatic robot programming precisely in situations where there is a wide variety of products within the same product families.

How does QPC work?

By using parametric data, QPC can quickly and accurately generate programmes for different product variants, regardless of complexity or specifications. This means that companies are no longer stuck with standard programmes for every variation on the parent product, but can instead dynamically generate customised welding programmes, sometimes within 30 seconds. Whether it’s adjusting the length, width or other parameters, QPC ensures that every product within the family is manufactured with the same precision and quality.

Parametric data

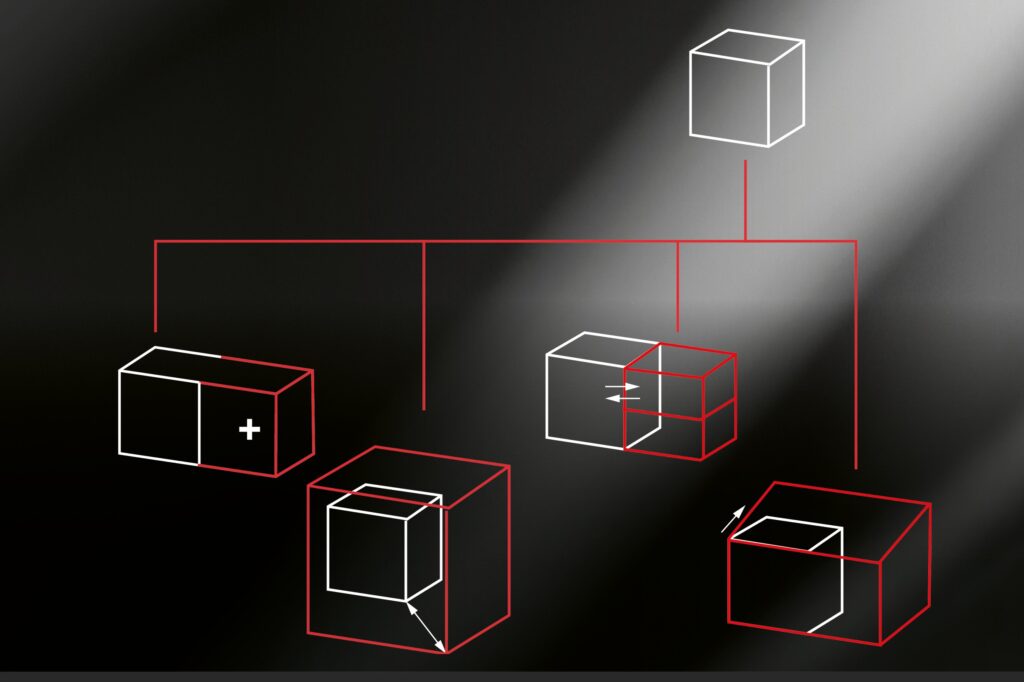

Parametric data and the creation of a database are necessary for the automatic generation of robot programmes with QPC. In this database, a parent programme is created based on the already known parametric data. This includes the welding parameters as well as information about, for example, fixed spacing between elements, type of welds, the number of corners and/or torch positions.

The QPC software can then automatically generate robot programmes by scaling, expanding and extending the master programme until it meets the requirements of the specific workpiece to be welded. If a product contains several elements with a fixed spacing, the QPC software will calculate the number of elements based on the total length entered and add the correct welds for all elements to the overall programme.

QPC Interface

QPC can be integrated into the production process in a customer-specific manner. For example, the software can be implemented with an interface where the operator enters the correct dimensions of the product to be welded on a screen next to the robot installation, after which QPC immediately calculates the welding programme. However, QPC can also play an important role in the further automation of the production process. Think, for example, of the (automated) scanning of a QR code containing the information required for QPC. After scanning this QR code, the QPC software will immediately start generating a welding programme for that specific product based on the source data entered.

Tilbox

One of our customers, the Tilbox company from Valkenswaard, uses QPC on a daily basis for the production of superstructures and substructures for trucks and trailers, where programmes can be generated within 30 seconds.

Advantages of QPC at a glance:

By using parametric data, QPC can quickly and accurately generate programmes for different product variants, regardless of complexity or specifications. This means that companies are no longer stuck with standard programmes for every variation on the parent product, but can instead dynamically generate customised welding programmes, sometimes within 30 seconds. Whether it’s adjusting the length, width or other parameters, QPC ensures that every product within the family is manufactured with the same precision and quality.

Parametric data

Parametric data and the creation of a database are necessary for the automatic generation of robot programmes with QPC. In this database, a parent programme is created based on the already known parametric data. This includes the welding parameters as well as information about, for example, fixed spacing between elements, type of welds, the number of corners and/or torch positions.

The QPC software can then automatically generate robot programmes by scaling, expanding and extending the master programme until it meets the requirements of the specific workpiece to be welded. If a product contains several elements with a fixed spacing, the QPC software will calculate the number of elements based on the total length entered and add the correct welds for all elements to the overall programme.

QPC Interface

QPC can be integrated into the production process in a customer-specific manner. For example, the software can be implemented with an interface where the operator enters the correct dimensions of the product to be welded on a screen next to the robot installation, after which QPC immediately calculates the welding programme. However, QPC can also play an important role in the further automation of the production process. Think, for example, of the (automated) scanning of a QR code containing the information required for QPC. After scanning this QR code, the QPC software will immediately start generating a welding programme for that specific product based on the source data entered.

Tilbox

One of our customers, the Tilbox company from Valkenswaard, uses QPC on a daily basis for the production of superstructures and substructures for trucks and trailers, where programmes can be generated within 30 seconds.

Advantages of QPC at a glance:

- Shortest possible cycle time

- Maximally optimised programmes

- No programming time

- Based on textual data of a product

- Can use parametric data from CAD software

- Various input options

- Manual

- Load parameters

- Scan QR code