Tilbox shortens route from order to welding robot

The Valkenswaard-based supplier of superstructures and substructures for trucks and trailers is investing in further automation of its production process. As a next step, Tilbox has commissioned a Valk Welding welding robot with an automatic programming system, which has significantly reduced the workflow from work preparation to welding robot. “We can have a welding programme for a box ready within 30 seconds. The extra capacity has enabled us to shorten delivery times on this line. This means we can produce more intelligently and serve the market better,” says Dion van Dommelen, the system engineer responsible for the renewal process.

Trucks and trailers are often equipped with a toolbox (or chest) for safe storage of tools. “Although body builders can make their own chests, they still order them from us because we can do it faster and cheaper thanks to our specialisation. However, orders are often only placed once a customer knows how much space is available. Delivery time therefore plays an important role. These are often single items or small quantities. In addition to customisation, in most cases there is a high degree of standardisation, with variations mainly in width, height and depth.”

With the welding robot or manually?

We already weld standard boxes using a welding robot based on a number of fixed programmes. However, in the case of non-standard sizes, adjusting the welding programme takes so much time that the decision to weld manually was quickly made. We wanted to find a way to create welding programmes quickly. The question was which player in the market could help us with this. Valk Welding had experience in this area and, based on previous projects, was able to show us how to use macros in QPC to adjust existing programming blocks, thereby eliminating the need to reprogram every recurring operation,” Dion continues.

Quick Programming Configurator (QPC)

QPC is Valk Welding’s proprietary software development, specifically designed to simplify and even automate the programming of welding robots within product families. As soon as a customer places an order via Tilsmart, the information is available and the programme can be generated using QPC software.

Repetitive operations are recorded in macros from the parent programme. By importing the macros into the DTPS programming system for Panasonic welding robots, a programme for the welding robot can often be ready within half a minute. This results in considerable time savings in work preparation. Tilbox has developed an online tool that allows customers to assemble their own boxes. Once the order has been placed, the data is sent to the robot. Using the QPC software, a programme can be generated quickly and the order can be produced.

See also: http://tilbox.nl/productconfigurator/

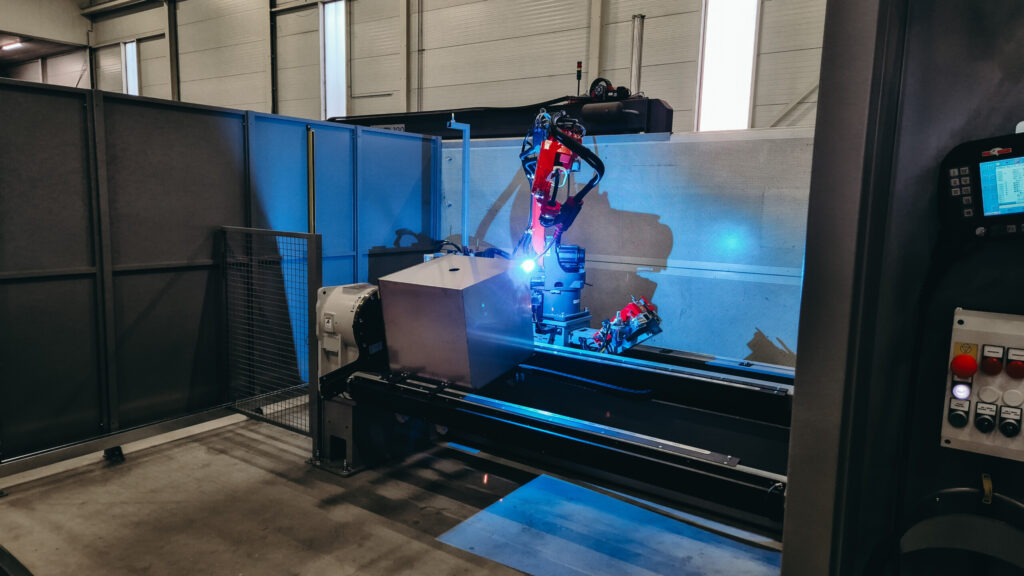

TRACK-FRAME-E with 2 clamping stations

The system installed by Valk Welding consists of a Panasonic welding robot on a track that operates two clamping stations, each with a manipulator. The manipulator is suitable for certain types of boxes that fall within a specific range. Approximately 90% of these types of boxes fall within the range; the few exceptions are welded as before.

Responding to further growth

“We want to continue to grow by providing our customers with optimal support through our service and products. Our online ordering tool not only offers comprehensive information, but also makes the ordering process simpler and more efficient. In addition, the investment in our new welding robot system ensures that we remain flexible and are ready to realise the increasing production capacity,” concludes director Gertjan Grimbergen.